21November 2025

When winter hits Camden, Gloucester, or Burlington County, the damage to low-slope and flat roofs isn’t always from the weight of snow—it’s the brutal freeze-thaw cycle. Many property managers and commercial building owners look for a quick fix in a can, asking if winter roof coatings can withstand this constant stress.

The expert answer is: some can, but most popular, cheaper coatings will fail spectacularly. We’ll break down which materials survive the rapid temperature shifts of New Jersey winters and what separates a temporary patch from a long-term, protective barrier.

The Enemy: How New Jersey’s Freeze-Thaw Cycle Destroys Standard Coatings

The single biggest enemy of any roofing material in the Garden State is the freeze-thaw cycle. This means temperatures frequently fluctuate above and below freezing, sometimes multiple times within a single 24-hour period.

The Mechanism of Coating Failure:

- Moisture Penetration: Water, often from melting snow or a winter rainstorm, seeps into microscopic cracks, pinholes, or failed seams in the roof coating.

- Expansion & Pressure: When that water freezes, it expands by about 9%. This expansion exerts immense pressure, widening the cracks and stressing the coating’s adhesion.

- Peeling & Blistering: As the ice thaws, the process repeats. This constant back-and-forth motion quickly causes low-quality coatings to blister, crack, and peel right off the underlying membrane.

If your roof coating is prone to absorbing water, it’s going to fail during a New Jersey winter. This often leads to hidden leaks and trapped moisture that cause damage until the spring thaw.

For commercial or multi-family properties that require immediate assessment, contact us on our Commercial Roofing Contractors page.

The Chemistry of Survival: Silicone vs. Acrylic in Freezing Temps

This section fills the knowledge gap by explaining exactly why certain coating chemistries crumble under cold stress, and which ones an expert uses to prevent leaks.

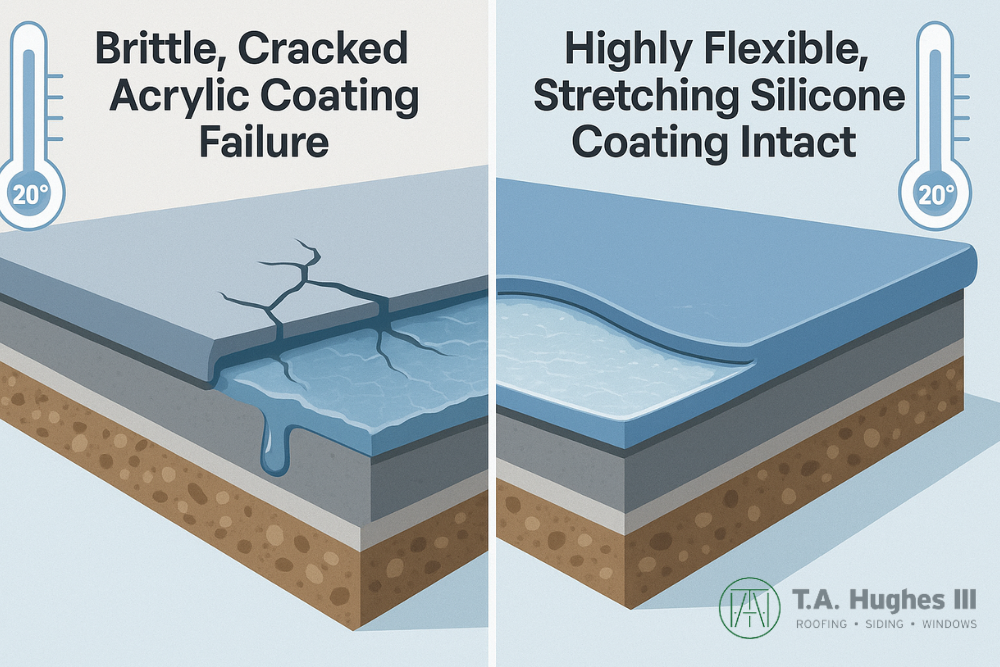

Acrylic Coatings: The Cold-Weather Risk

Acrylic coatings are popular because they are water-based, low-odor, and affordable. They are excellent for UV reflection in the summer but present a major risk in winter:

- Water-Based Chemistry: Since they are water-based, acrylics can improperly dry or even freeze inside the pail if not stored or applied above 40°F. Once frozen, they are ruined.

- Brittle in Cold: They become brittle in very cold temperatures and lack the elasticity to handle freeze-thaw expansion, making them prone to cracking and rapid peeling.

Silicone and Urethane Coatings: The NJ Solution

These are the only coating systems professionally recommended to survive the NJ freeze-thaw cycles.

- Silicone Coatings: They are the best choice for ponding water because they are hydrophobic (water-shedding) and create a seamless barrier that resists water infiltration. Crucially, their high flexibility allows them to expand and contract with the roof during temperature swings without cracking.

- Polyurethane/Urethane Coatings: These are incredibly strong and durable, offering excellent resistance to foot traffic and impact. Like silicone, they are typically solvent-based and retain high tensile strength and elongation in cold, variable weather.

- Note: Combined Urethane-Silicone (Ure-A-Sil) systems offer superior durability and moisture resistance.

The T.A. Hughes Difference: Surface Prep is 90% of the Job

A quality coating material is irrelevant if the roof is not perfectly prepared. This is the difference between a roof lasting 2 years and lasting 15 years.

We never just roll a coating onto an existing membrane. Our professional preparation steps ensure the new layer truly adheres and locks out moisture, especially in areas like Gloucester County.

- Moisture Survey: Before applying anything, we perform a non-destructive test to ensure no moisture is trapped under the existing membrane. Trapped moisture will vaporize when heated by the sun, causing the new coating to blister and fail instantly.

- Detailing Seams and Flashings: This is the most critical step. We apply specialized fabric and sealants to all pipe boots, vents, and seams before the main coating application. This addresses the high-risk areas where 90% of leaks originate.

- Perfect Adhesion: We only apply coatings within manufacturer-specified temperature ranges (usually above 40°F to 50°F) to ensure the coating fully cures, bonds properly, and won’t get “washed off” by unexpected winter rain.

Coating vs. Replacement: When a Winter Patch Becomes a False Economy

Property managers need to understand the true cost-benefit analysis. A coating is a restoration, not a replacement.

| Feature | Coating for Life Extension | Full Roof Replacement (TPO, EPDM) |

|---|---|---|

| Goal | Extend lifespan of an existing, functional roof. | Permanent removal of failed system down to the deck. |

| Suitable For | Structurally sound roofs with minor seam issues or UV degradation. | Substrate that is soft, spongy, has widespread leaks, or wet insulation. |

| Lifespan | 10–15 years | 20–30+ years |

| Cost Risk | Low upfront cost, but high risk if applied over wet insulation (guaranteed to fail). | Highest upfront cost, but lowest long-term maintenance cost. |

If your roof is over 20 years old and has repeated leaks, a coating is a temporary solution that will waste money when the inevitable full replacement is needed. Use our Roof Repair vs. Replacement Calculator to help determine which option is best for your current situation.

Conclusion: Don’t Guess, Assess: The Winter-Proof Solution

To protect your property from New Jersey’s unpredictable freeze-thaw cycles, skip the cheap, water-based acrylics. Trust only in professional-grade silicone or urethane systems applied with meticulous surface preparation.

Before winter locks in your roof damage, let the experts at T.A. Hughes Roofing assess your flat or low-slope roof. We’ll give you an honest answer if a coating is a viable 10-15 year solution or if you need a long-term commercial roof repair.

Contact T.A. Hughes Roofing for a Commercial Roof Assessment today at tahughes.com.

FAQs

- Q: Can you apply roof coating when it is freezing in New Jersey?

- A: Generally, no. Most coatings (especially water-based acrylics) require the ambient temperature to be above 40°F to 50°F during application and curing. Attempting to apply coatings in freezing temperatures leads to poor adhesion, improper bonding, and guaranteed failure. Fall is the ideal window.

- Q: How long does a quality silicone roof coating last in South Jersey?

- A: A high-quality, professionally applied silicone roof coating system can provide a seamless, watertight barrier for 10 to 15 years, provided the substrate (the roof deck underneath) is in good condition and prepared correctly.

- Q: What is the first sign a winter roof coating is failing?

- A: The first signs of failure in an improperly applied coating are usually small blisters or bubbles, followed by cracking along the seams or flashings. These occur when the coating absorbs water and is damaged by the expansion caused by the freeze-thaw cycle.

- Q: Do roof coatings help prevent ice dams in New Jersey?

- A: Not directly. Ice dams are caused by poor attic insulation and ventilation that allows heat to melt snow, which then refreezes at the cold eaves. However, reflective coatings can help prevent heat loss and make the roof deck more water-resistant, reducing the water damage caused by ice dams.